Metalworking

Practical Action

How to Make a Folding Machine for Sheet Metal Work - Workshop Equipment 1

Rob Hitchings, Practical Action Publishing

Bending rollers are used to make drums and pipes. They consist of three horizontal rollers,

one above the other two, arranged so as to bend continuously a sheet fed through them. The

top roller is adjustable in height to set the radius of curvature of the bend. The rollers are

driven either by a handwheel or by power.

How to Make a Rolling Machine for Sheet Metal Work - Workshop Equipment 3

Rob Hitchings, Practical Action Publishing

Specialised bending machines, particularly used by tinsmiths, include burring machines

(usually called jennies), which are used for flanging the ends of containers in preparation for

wire edging or for making a folded seam; wire rolling machines, for rolling down the edge of a

sheet over edging wire; and beading machines, which, by rolling the sheet between shaped

rollers, raise a bead round, for example, a drum. Combination machines are available, which

will carry out several tinsmiths’ operations (flanging, beading, wire rolling, crimping, etc), by

interchanging rollers.

If you are going to perform a particular action on a regular basis such as creating ridges in

the metal it is worth getting some extra equipment. This could be as simple as a low cost

jenny. See the Practical Action Technical Brief How to Make a Strengthening Ridge in a

Bucket and How to Make a Metal-bending Machine - Workshop Equipment 10 by R.D.

Mann, Practical Action Publishing.

Three dimensional bending can be carried with a press and dies. A 5-ton fly press can be

used to stamp items such as small electrical switch covers. Dies can be made of wood, zinc--

based alloy, mild steel, or hardened steel. It is also possible to use a rigid die in conjunction

with a rubber block. Presses are best suited to batch production. For one off items, hammers

and a variety of dollies which are held behind the sheet being worked can be used.

Pipe Bending

Various low-cost approaches can be applied to this

process as demonstrated in the following two

documents. See the Practical Action Technical Brief

Pipe bending and How to Make a Pipe-bending

Machine - Workshop Equipment 5, Michael Walsby,

Practical Action Publishing.

Cutting and machining

Cutting can be done with a hammer and cold chisel,

which is hard work but often preferable to saws that

wear too quickly.

Another common method is flame cutting if welding

equipment is available.

Tinsnips are used for light work on thin material (up to

about 1 mm steel or 1.5 mm on softer metals). They

are cheap and versatile, but slow, and tend to buckle

the edges of the cut metal.

Various patterns of snips are available, some intended

for cutting deeply into large sheets and others made

more manoeuvrable within the cut. Some have straight

blades, and others, intended particularly for cutting

holes and curved edges, have curved blades.

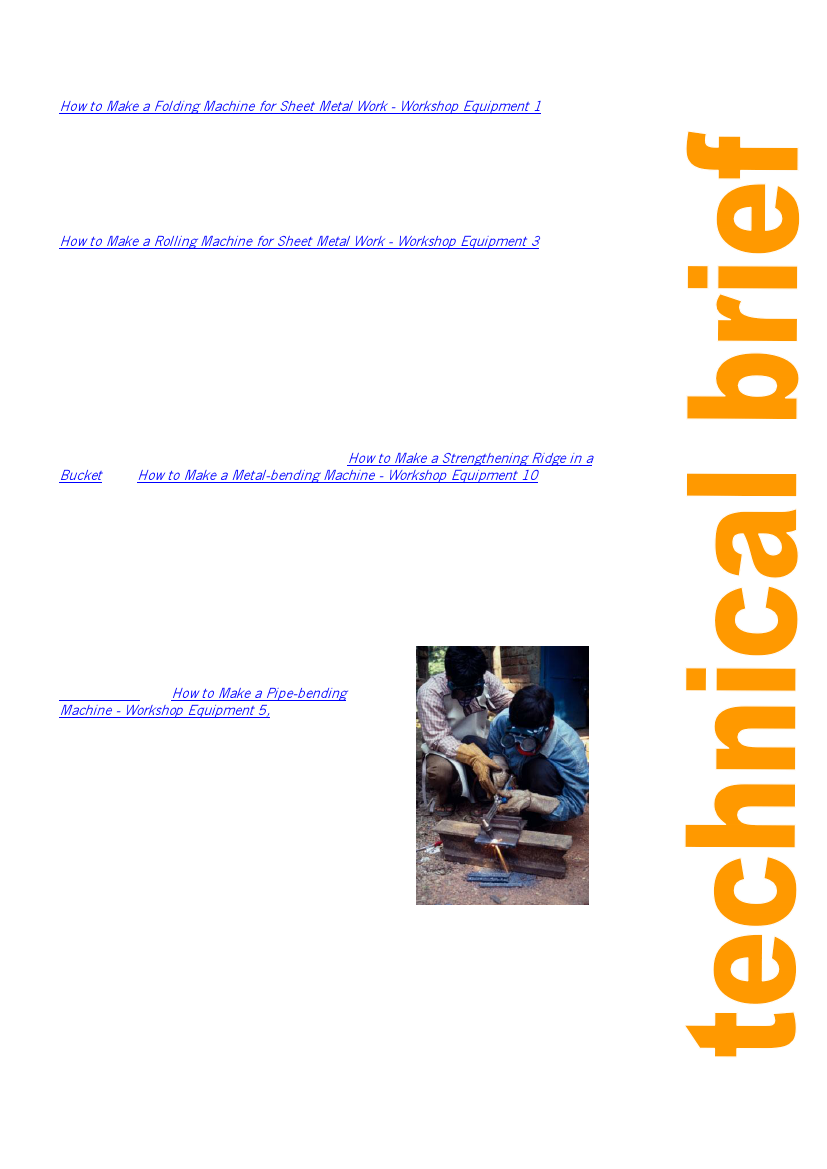

Figure 4: Flame cutting. Practical

Action organised training for

Asaduzzman Munshi in welding. As a

result he has now started a small

metal workshop of his own, earning Tk

3000 monthly (2000). In the process

of cutting parts for a three-wheel

rickshaw structure. Photo credit:

Practical Action/Zul

3